For several decades, material requirements planning (MRP) has been the standard method for manufacturing and inventory planning. But in recent years it has come under criticism, and any manufacturing shops have adopted other approaches, such as kanban or lean manufacturing.

The fact that MRP has been around for so long is an indication of its value, but its calculations are complex, and its constraint that safety stock levels (to cover demand and supply uncertainty) are fixed and in one location, is limiting.

The problem is that MRP was developed at a time when businesses could use static demand forecasts over an extended time period to allow for long production runs. In the modern world, long runs are rare and demand can be highly variable. Consequently, new approaches are being sought.

What does a new material planning approach require?

A new approach needs to incorporate a number of aspects.

- Combine the pros of MRP with modern, advanced demand management tools

- Recognize that demand can be highly variable and that long production runs are unlikely.

- Appreciate that inventory is an asset (‘lean’ considers it a waste) that can be optimized to make best use of working capital, without adversely affecting customer service levels.

- Realize that safety stock is necessary but its levels can be dynamic and it should be optimally located within the supply chain.

- Leverage the modern, sophisticated forecasting and modeling techniques that are now available.

- Ensure inventory is forecast and modeled for multiple locations.

- Employ standard and accepted metrics for assessing forecasts and service capability.

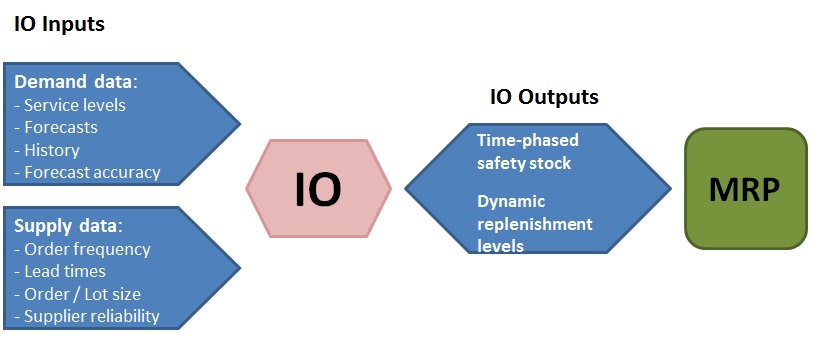

Some people have proposed re-writing MRP with a demand-oriented focus, but that could be a “change too far” for many manufacturing organizations. Instead, we would advocate keeping MRP but adding a stage beforehand to provide better demand estimates. That stage we call Inventory Optimization (IO).

IO uses demand and supply data that a business already has available, in various locations, to forecast the appropriate stock-levels and order requirements.

There are four steps needed to accomplish this.

- Categorize and analyze stock codes according to certain criteria (profitability, revenue, demand frequency), using historical supply and demand data, to identify critical items that require detailed forecasting; this will also help to determine seasonal fluctuations.

- Apply different techniques to get the best forecast of customer demand by item; this can be fine-tuned over time, using actual past data to ensure future forecast accuracy.

- Create stock policies and model them to determine the best balance between customer service and inventory levels; a key outcome is the safety stock required to buffer unpredictable fluctuations in demand or supply and dynamic replenishment levels.

- Work the plan according to the forecast and the policy.

MRP is still valuable. It provides answers to the critical questions – ‘what do I make?’ and ‘what do I buy?’. Now, however, there is a solution to give better answers to the following questions – ‘when do I make?’, ‘when do I buy?’, ‘what do I stock, and where?’.

So rather than throwing your MRP process out and trying a completely new material planning process, with all its attendant complications and changes, you might want to consider adding the IO stage at the start. We have customers already using it, and it’s also won an award.