Procurement in manufacturing companies is often not done correctly. It’s not because key business requirements are missed, but because the totality of what can be influenced is ignored. With direct and indirect materials making up at least 50% of typical manufacturing costs, the procurement function could be re-imagined so companies can be more responsive to customer demands and more agile when dealing with supply chain challenges. As a recent article notes:

“for procurement to lead the way, companies will want to reimagine not just what the function does but also how it operates and which new capabilities it will need”

(McKinsey – Reimagining procurement for the next normal)

Current procurement focus

If asked about their work, many procurement managers will say they are ensuring orders are placed properly, that they are controlling the stock and making sure that there is stock on hand so that the factory doesn’t stop. They have a contract with a supplier who delivers on time, and who charges acceptable prices. This meets all their key performance areas.

What this response shows is that they do not fully understand the impact procurement has on stock.

- If their main concern is that manufacturing doesn’t stop due to lack of stock, they are almost certainly overstocking the warehouse.

- Purchasing is not integrated with how materials are consumed in production, neither does it have insight into how lots and batches are stored and used, so there is minimal information about inventory and possible obsolescence.

- A single supplier focus means that there is a high risk if the supplier closes its doors.

The procurement process

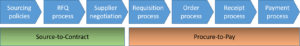

The procurement process doesn’t start with raising a purchase order and sending it to a supplier. It starts before that. For a business to re-imagine and transform their procurement process, it needs to examine how the main processes of Source-to-Contract and Procure-to-Pay are implemented in an integrated way, and not just how procurement performs them, but also how other functions within the company are affected.

Sourcing

The first stage of reimagining procurement is to look at sourcing strategies. The two main pillars of sourcing will be alternative suppliers and alternate pricing. The best way to ensure this works properly is to automate the Request for Quote (RFQ) process via a supply chain portal.

RFQs extend a formal invitation to suppliers to tender on the supply of goods or services. Automating this capability streamlines the process of the RFQ creation from an initial requisition and allows suppliers to service the RFQ online. Submitted proposals are stored in the online supply chain portal. An automated RFQ process provides transparency of the tender process and assists buyers in making informed procurement decisions quickly and easily as they can compare offerings from different suppliers. The reduction of manual processes also decreases the manual workload.

The supply chain portal streamlines collaboration between buyers and suppliers and minimizes document handling. Staff from different departments, and from customer and supplier companies, can interact on the platform, easing the flow and availability of information. This will also reduce the risk of fraud.

In the case of supply chain disruption, automating this part of procurement can speed up the process of fixing a broken supply chain and provides buyers with the agility needed to manage unreliable logistics or sourcing situations.

Procuring

To ensure that the right materials are ordered there has to be a way of anticipating what is needed so that the factory can still operate and so that suppliers can plan adequately for what will be ordered. This is typically done by forecasting based on historical data. With an integrated system that connects manufacturing and procurement, the past data on what raw materials are consumed by production can be input into a forecast model to generate a set of future orders.

With the forecast of orders established, the requisition process can be streamlined so that only unplanned material requirements need to go through an approval process.

Knowing what future orders will be like, this information can be passed to suppliers to help them to plan how to run their operations to fulfil the anticipated orders. Furthermore, with that order information, it is easier to negotiate delivery agreements and pricing based on volume.

If stock is being ordered correctly, at an agreed price, and contracts are in place, the Accounts Payable process becomes easier as there are no arguments around payments. An integrated system enables the ordering system to improve warehouse efficiencies by guiding inventory receipts to designated stock bins.

Agile procurement

The ability of procurement to quickly update orders in response to a sudden change in customer demand is simplified if the previous steps are already in place. For example, if a customer moves an order forward, the near-term delivery agreements with suppliers can be updated to get raw materials sooner. Combining the safety stocks that the manufacturer has with those that its suppliers hold will allow procurement to act with agility and ensure stock is available for production.

Procurement can be a significant driver of an organization’s pandemic recovery efforts. Forward-looking companies should be looking at how procurement can be equipped with technology solutions to make it more effective and enhance the value that it can deliver.