In a make-to-order manufacturing company, think about the amount of time it takes to move from quote to sale to production to final payment – and the number of handoffs it takes to get there.

Your sales rep quotes a price and closes a deal. Engineering draws up a CAD design. Manufacturing creates the product. Logistics ships it to your customer. Finance follows up, and eventually you receive your payment. From end to end, it can be a challenge to ensure that everything happens smoothly, accurately, efficiently and profitably.

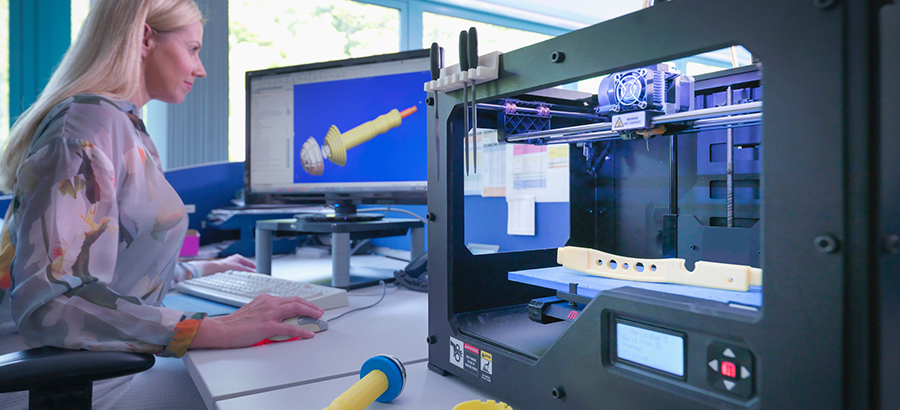

The transition between engineering and manufacturing is perhaps the most critical – specifically when it comes to creating a Bill of Materials (BOM) from your CAD designs. Your expensive engineers spent a lot of time designing the product, and they are now handing over to another expensive department, manufacturing, to produce it. You need this handover to be accurate and timely.

If you currently have engineers manually entering BOM’s into your ERP system, you are introducing delays and errors, both of which are very costly.

Even seemingly small errors have magnified effects downstream. A mistyped quantity, a missing component, an incorrect item code or a dropped decimal point can cause big problems, all of which cost money:

- Purchasing orders the wrong parts, then have to expedite the correct ones

- Downtime in production due to shortages of the correct parts

- Rework in production because the product was not manufactured to the engineering design

- Juggling the production schedule in reaction to the above issues

Not only can these mistakes create headaches for your team, but they can cause dissatisfied customers to return wrong or faulty products, a loss in profitability, a drop in reputation or even a lawsuit. The cost of that one typo could be thousands of dollars.

That’s where automation pays off. When you integrate your CAD and ERP systems, your team can create BOMs from your design files in minutes, without risk of human error. With this one improvement, most companies can reduce the engineering release process by up to 80 percent!

A perfect match: 3 benefits when CAD meets ERP

A tool like CADTalk is a proven way to integrate your CAD and ERP systems. You can reduce lead time, realize profits sooner and gain other benefits such as:

- More accurate BOMs

Automated processes eliminate human error because they follow a set of rules the same way, every time. This results in correctly manufactured parts, better scheduling and planning, more accurate costing and more overall trust in the process.

- Increased efficiency for engineers

Rather than your highly-skilled and highly-paid engineers spending hours manually creating new records such as part numbers, BOM’s, and routings, a smart integration will automatically import the CAD data into the ERP in minutes. The same applies to part revisions.

- Reduced costs

Time is money. Your engineers are expensive, so doing data entry is not the best use of their time.

In addition, with more accurate data, you’ll also avoid costs from rework, incorrect inventory, data clean-up, customer returns and potential legal liabilities.

A win-win: Happy customers and a healthy bottom line

Importing a BOM from your CAD to your ERP accurately and efficiently plays a huge role in ensuring that your customers receive the right product, in the shortest lead time, at the best price and profit margin. Getting it wrong has significant and costly downstream effects.